Fasteners and Machining: Necessary Parts for Accuracy Production

Fasteners and Machining: Necessary Parts for Accuracy Production

Blog Article

Unveiling the Ins And Outs of Bolts and Machining Processes for Ideal Efficiency

In the realm of design and manufacturing, the option of bolts and the ins and outs of machining procedures play a crucial function in establishing the supreme efficiency and sturdiness of a product. From the relatively straightforward job of picking the appropriate kind of bolt to the facility precision machining techniques employed, every action in this procedure demands thorough focus to detail. As we start this expedition into the world of bolts and machining, we will reveal the refined yet vital factors that can dramatically affect the performance and quality of the end product, clarifying the often ignored facets that can make all the difference in attaining ideal efficiency.

Importance of Correct Bolt Selection

Picking the suitable bolts is important in making sure the structural integrity and longevity of any mechanical setting up. Fasteners play an essential duty in holding elements together firmly, with the best choice adding considerably to the general performance and reliability of the assembly. When choosing bolts, aspects such as product compatibility, ecological conditions, load-bearing ability, and simplicity of installment should be carefully thought about to assure optimum efficiency.

Inappropriate fastener choice can bring about a variety of problems, consisting of helping to loosen, corrosion, and even architectural failure. Utilizing bolts that are not fit to the specific demands of the setting up can endanger its capability and position safety and security threats. As a result, developers and engineers need to thoroughly review the application requires and choose fasteners that meet or exceed the needed criteria and requirements.

Moreover, the proper fastener option process entails assessing the joint layout, expected loads, vibration levels, and possible thermal development or contraction to ensure that the picked fasteners can withstand the operating conditions efficiently. By focusing on correct fastener selection, suppliers can boost the quality, sturdiness, and performance of their mechanical settings up.

Kinds and Attributes of Fasteners

A necessary aspect of mechanical settings up exists in understanding the varied types and special features of bolts utilized in numerous commercial applications. Fasteners are crucial components that hold structures with each other, making sure security and capability. There is a large range of bolts offered, each designed for particular objectives based upon the application needs. Common kinds of fasteners include screws, screws, nuts, washers, rivets, and pins.

Screws are threaded bolts that are commonly utilized to sign up with two or even more parts together. Nuts are inside threaded bolts that mate with bolts to hold elements with each other. Washers are slim plates that disperse the load of a bolt, protecting against damage to the product being attached.

Recognizing the features of each sort of bolt is necessary for choosing the ideal one for a specific application, guaranteeing ideal performance and reliability of the mechanical setting up. Fasteners and Machining.

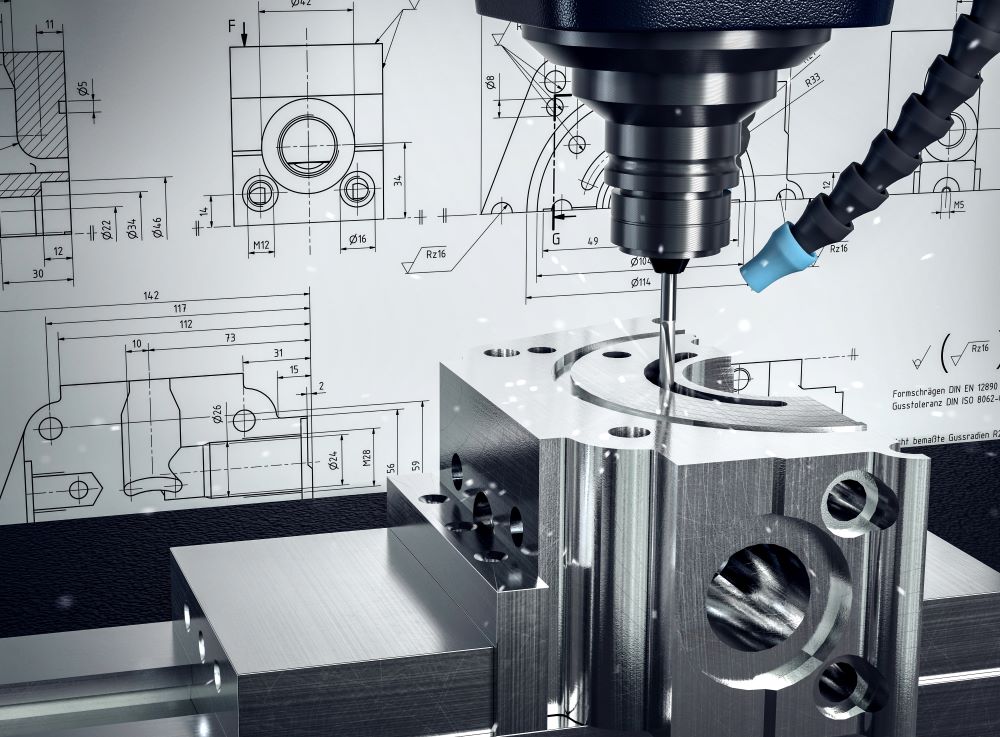

Accuracy Machining Methods for Effectiveness

The elaborate design requirements of numerous bolts require employing precision machining strategies for ideal effectiveness in manufacturing processes. Accuracy machining is vital in guaranteeing that fasteners fulfill the specific specs needed for their desired application. Among the primary techniques made use of in precision machining is Computer Numerical Control (CNC) machining, which enables high degrees of precision and repeatability in the production of bolts. CNC makers can performing complicated cuts and shaping procedures with very little human intervention, leading to raised effectiveness and consistency in the production procedure.

By making use of accuracy machining strategies, makers can boost the quality of fasteners, minimize material waste, and enhance overall production performance. The usage of innovative machining processes aids make sure that bolts satisfy industry standards and customer expectations for efficiency and integrity.

Elements Influencing Machining Refine Performance

Various variables play a significant role in identifying the performance of machining processes in the manufacturing of fasteners. Enhancing these specifications based on the certain demands of the bolt being created is crucial to attaining specific and cost-efficient machining.

Equipment strength and security likewise play a crucial role in determining machining procedure efficiency. A secure maker with very little vibrations can enhance accuracy and prevent device wear, causing better total efficiency. Furthermore, the skill and experience my website of the machine driver can not be taken too lightly. A well-informed driver can make real-time changes, troubleshoot problems efficiently, and make certain that the machining procedure runs smoothly, inevitably impacting the final top quality of the bolt.

Top Quality Control Actions in Production

Variables affecting machining procedure efficiency, such as reducing tool choice and device stability, directly impact the implementation of top quality control procedures in manufacturing. Quality control measures are important in making certain that items fulfill the needed requirements and specs. In the manufacturing procedure, various strategies are employed to keep high quality criteria. Examination and testing play a crucial role in determining any type of deviations from the wanted end result. Normal maintenance of machining equipment is additionally essential to support high quality control. Calibration of devices and devices is required to ensure exact and accurate manufacturing procedures. Furthermore, implementing discover this standard operating procedures and methods can assist in keeping consistency and quality throughout the assembly line. Quality control gauges not only concentrate on completion item however also on every stage of the production process to stop flaws and mistakes. By adhering to rigid quality assurance actions, producers can boost customer satisfaction, develop a credibility for integrity, and ultimately accomplish optimum performance in their machining processes.

Verdict

In verdict, picking the right fasteners and utilizing try this site precision machining methods are crucial for optimum efficiency in manufacturing processes. Understanding the types and qualities of bolts, together with aspects affecting machining procedure performance, can cause boosted performance and quality assurance measures. By paying attention to these complexities, producers can achieve higher degrees of efficiency and integrity in their items.

In the realm of engineering and manufacturing, the option of bolts and the ins and outs of machining processes play a critical role in establishing the best efficiency and toughness of a product (Fasteners and Machining). One of the primary techniques made use of in accuracy machining is Computer system Numerical Control (CNC) machining, which allows high levels of precision and repeatability in the production of fasteners. The use of advanced machining processes aids make sure that fasteners fulfill sector requirements and customer assumptions for performance and integrity

In final thought, selecting the appropriate bolts and utilizing accuracy machining methods are vital for optimal performance in making processes. Recognizing the types and characteristics of bolts, along with elements affecting machining process efficiency, can lead to improved performance and quality control actions.

Report this page